As you already know, the strength of a 3D print is a critical factor that can determine the success or failure of a project. One of the key elements that can significantly affect the strength of a 3D print is the infill pattern.

Infill patterns are the internal structures that the 3D printer creates to fill the object from the inside. They can vary in shape and density, and each pattern type has its own unique properties.

Now, you might be wondering, which infill patterns are the strongest? Well, that’s a great question. There are several infill patterns that are known for their strength. For example, the honeycomb infill pattern is often praised for its balance of strength and material usage. The cubic or gyroid infill is often considered the strongest. While rectilinear pattern, which is essentially a simple grid, is the least strong and efficient for non-stress objects. Here we will cover everything in detail and find out the strongest infill.

Table Of Contents

Why the Strongest Infill Pattern Matters:

The strongest infill pattern matters because it directly impacts the durability and stability of the printed object. For instance, if you’re printing a tool that needs to withstand a lot of pressure or force, a stronger infill pattern like the honeycomb or the 3D rectilinear would be ideal. These patterns provide excellent strength and rigidity, making the final product more robust and durable.

On the other hand, if you’re printing an object that doesn’t need to bear much weight or force, you might opt for a less dense infill pattern, like the rectilinear or the grid. These patterns use less material and take less time to print, but they also result in a less sturdy object.

Here are some points on why the strongest infill pattern matters:

1. Infill patterns significantly impact the strength and durability of 3D printed objects.

2. The stronger infill patterns provide better structural integrity to the printed objects.

3. Objects printed with strong infill pattern can withstand more pressure and stress.

4. Strong infill patterns can also influence the weight and material usage of the 3D printed object.

5. They can affect the print speed, as some strong infill patterns may take longer to print.

5 Strongest Infill Patterns In 3D Printing:

There are several different infill patterns that can be used in 3D printing, each offers different types of strengths and durability. So it’s important to choose the correct infill according to your 3D print requirement.

Here I will share the 5 strongest Infill patterns that can be used to enhance the durability and stability of your 3D-printed objects.

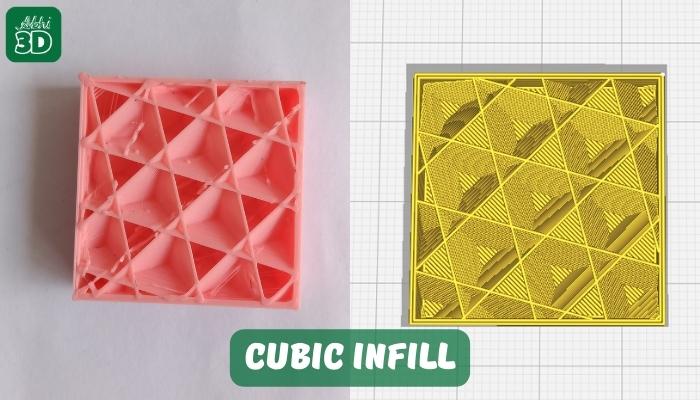

Cubic Infill is known for superior strength. This pattern creates three-dimensional grid of cubes providing strength in all directions, not just along one or two axes. This makes it an excellent choice for objects that need to withstand pressure or stress from multiple directions. So if you’re looking for the strongest infill pattern in 3D printing, the Cubic Infill is your best bet. It may not be material or print time efficient as compared to other infill but it surely will give you the strongest 3D prints.

The honeycomb infill, due to its unique geometric configuration, provides high strength and stability to the printed object, while also being efficient in terms of material usage when compared to Cubic infill.

The strength of the honeycomb infill comes from its hexagonal design. This design allows for equal distribution of stress across the entire structure, making it highly resistant to pressure from all directions. This is why the honeycomb infill is often the preferred choice for objects that need to withstand high levels of stress or pressure.

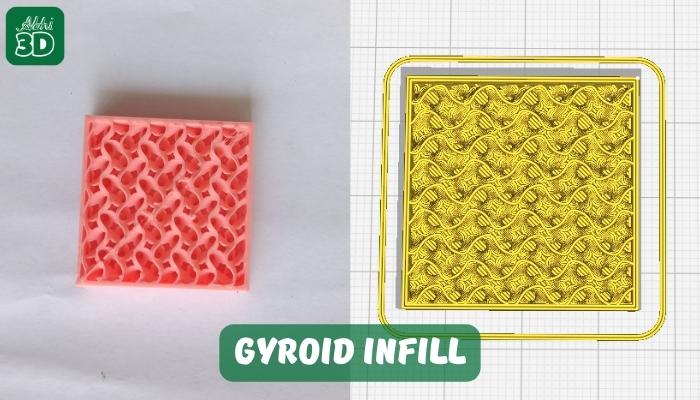

Next, we have Gyroid infill well-known for its complex structure and strength. It creates a triply periodic minimal surface infill, meaning it repeats in three dimensions while maintaining a continuous surface. It provides excellent strength, making it ideal for applications that require durability and resistance to various forces.

One of the most significant advantages of the Gyroid infill is its material efficiency. It uses less material compared to other infill patterns, such as the Cubic or honeycomb, while still providing comparable, if not superior, strength. This makes it a cost-effective choice for many 3D printing applications.

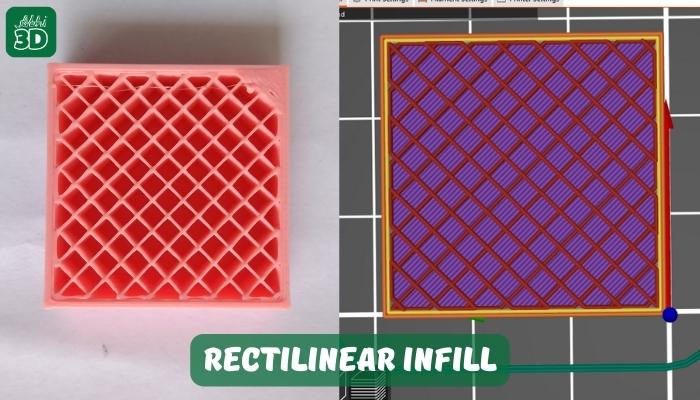

Rectilinear, Lines Or Grid Infill:

Rectilinear infill is one of the most common and fastest infills in 3D printing. It’s actually surprising that this infill still provides decent strength making it a perfect choice for those who are looking for balance in strength, material efficiency and print time.

The strength of a rectilinear infill comes from its straightforward geometry. The straight lines provide a strong backbone for the printed object, making it resistant to forces applied from different directions. This is particularly beneficial when the printed object is expected to bear loads or resist pressure.

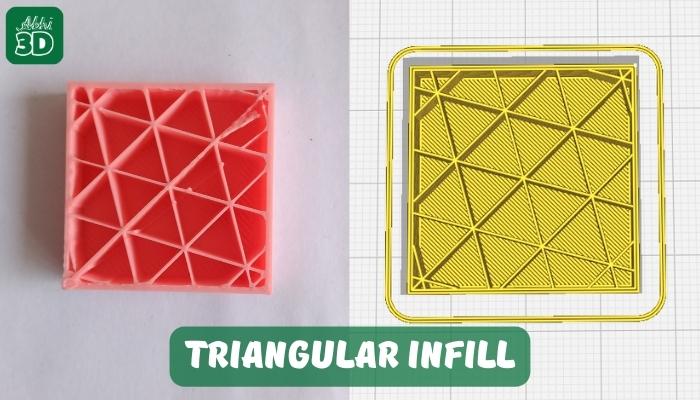

The last one in the list we have is Triangular Infill. This pattern is known for its excellent strength-to-weight ratio. The reason behind this is the inherent structural integrity of the triangle. It also provides decent strength to your 3D prints. This completes our top 5 list and next, we will share the stress test performed using different infill.

Comparing the Strongest Infill Pattern Test:

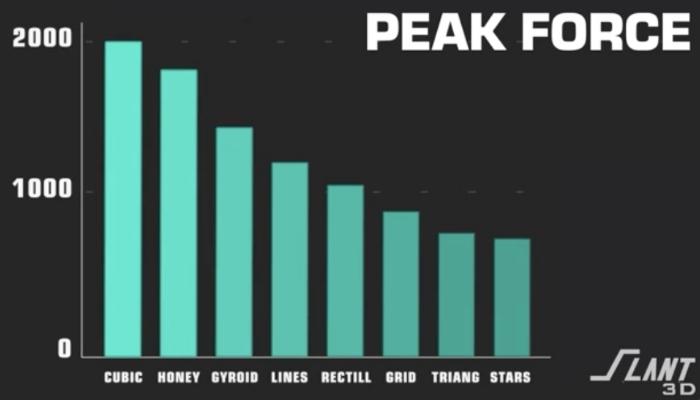

Slant 3D on YouTube did a compression test by using all different type of 3D infill in FDM printing. He found that Cubic infill is actually the strongest infill in 3D printing. The other infill which are quite strong are Honeycomb and Gyroid infill. Below is the chart shared in his video.

You can watch his full video here:

Important Note: You must consider using lines or rectilinear infill if you want to have faster printing with decent strength in your 3D print. These 2 infill are most commonly used because of their simple grid design-like structure.

Factors Affecting Strength Of 3D Printed Object:

If you are not satisfied with the strength of your 3D print even after using the strongest infill pattern. Then it’s important to note that there are many other factors that affect 3D print strength and durability. Let me share them with you here so you can make other changes to maximize the strength possible according to your requirements. Each of these factors can have an impact on the final product’s strength and durability.

1. Infill Density: This is the amount of material used in the infill. A higher density means more material, resulting in a stronger but heavier and more expensive print.

2. Infill Pattern: The pattern used can also affect the strength. Some patterns like the gyroid, cubic, honeycomb, or triangular patterns are stronger than others.

3. Material: The type of material used for printing also plays a role. Some materials like ABS or PLA have different strength properties and can affect the infill’s strength.

4. Print Speed: The speed at which the print is made can also affect the strength. Faster speeds can lead to weaker infills as the material doesn’t have enough time to properly bond.

5. Layer Height: The height of each layer can affect the strength of the infill. Thinner layers tend to create stronger infills as they have more surface area to bond with each other.

6. Print Temperature: The temperature at which the print is made can affect the strength. Higher temperatures can lead to stronger infills as the material is more fluid and can bond better.

I hope this article was helpful and gave you a detailed inside of how you can make your 3D print stronger. Let me know in the comments if you have any suggestions too.