3D printing, also called additive manufacturing, is a way to create objects by adding material layer by layer. The most popular material used in 3D printing is type of plastic known as Filament.

This additive manufacturing helps designers make complicated parts for machines, toys, airplanes, and cars much cheaper and faster than regular methods like forging, molding, or sculpting. It’s a super-efficient way to build any stuff. Normally, a 3D designer creates these objects using special computer designs called CAD (Computer Aided Designs) or by shaping them(Sculpting). Some of the famous software used for 3D designing are Blender, Maya, Fusion 360, Zbrush, and Nomad Sculpt.

Key 3D Printing Terms:

Important Terms To Understand Before You Understand How 3D Printing Works:

CAD(Computer Aided Design):

CAD stands for computer aided design. It basically means what you’re looking here is CAD software to create 3D design. The most popular 3D software are Blender, Maya, Fusion 360, Zbrush and many more.

In 3D printing with CAD, you should understand 3D Modeling and Sculpting. In 3D modeling, we make things like buildings, weapons, furniture, and vehicles. In Sculpting, we create organic shapes like animals and trees. That’s why people who sculpt are called 3D artists.

Now that you have created your 3D CAD design, you will need the design file in STL format. It’s a most widely used file format required for 3D printing.

On the technical side, an STL file is like a simple outline of a 3D design, kind of like connecting dots. Each shape is made of three vertices and a normal(a direction arrow). This arrow tells us which way the shape is facing and which side is the inside and which side is the outside. We put material on the outside part. On the other hand, a CAD file is described by its details and specific measurements, while an STL file is more like a rough estimate of the original design. That’s why the CAD file is more accurate, while the STL file is a simpler version. However, an STL file still has all the important information required for 3D printing. That’s why people use STL files as the standard for 3D printing.

3D Slicer & G-code:

This is the final part to get your design ready for 3D printing. It’s called “slicing” the STL file using the 3D slicer software like Cura. After slicing, you’ll have a Gcode file that you can save and use for 3D printing.

In simple terms, Gcode is a computer numerical control programming language that 3D printers understand. It’s like the instructions we give to our 3D printers to tell them what to make and how to make it.

3D printer is your printing machine which reads G-code digital file and follows instructions to create the physical object by depositing material(Filament) layer upon layer. There are different kinds of 3D printers, like Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

Printing Material(Filament):

Most 3D printers use plastic material called Filament, but the type of plastic can vary. For example, FDM printers often use PLA, ABS, or a mix of them. SLA or resin printers use a substance called Resin. And SLS 3D printers typically use nylon.

Extruder & Nozzle:

In Fused Deposition Modeling (FDM) 3D printers, the extruder is a part that heats, melt filament, extrudes the thermoplastic filament and nozzle deposits layer by layer in the build area.

Resin is a liquid 3D printing material used in SLA 3D printer which hardens when exposed to UV light. These SLA 3D printers use a laser to turn the liquid resin into solid plastic through a process called photopolymerization.

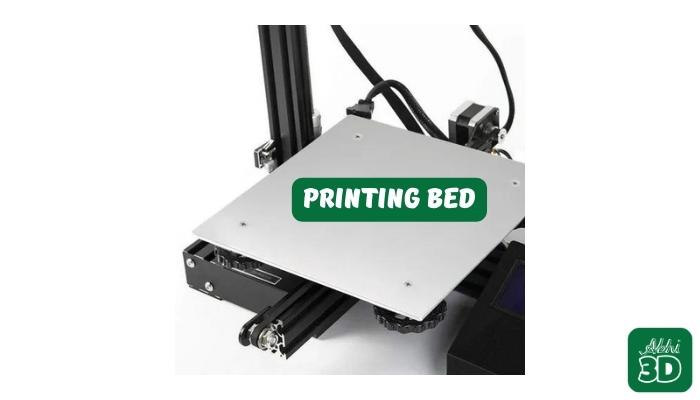

Printing Bed/Build Platform:

This is the surface where the 3D printer makes the thing. It can be heated or unheated, depending on the printer and material used. For good FDM 3D print strong bed adhesion is required.

Support:

We should know that a 3D printer works layer by layer, with each layer resting on the one below it. But in some designs, there are parts that stick out without much or any support from the layer below. This can lead to a bad print. To fix this, we can add support when preparing the 3D model for printing in slicer. When we set up the print, we can add extra material under the overhanging parts to make sure they come out nicely.

Infill means how packed the material is inside a 3D printed object. You can choose how much infill you want when you set up your design for printing in slicer. Keep in mind, the more infill you have, the longer it will take to print, but it will also be stronger.

Basic Of How 3D Printer Works:

This is how 3D printer works step by step:

Step 1: Put the printing material (filament) into the extruder.

Step 2: Next level the bed so the print will be nice and flat. It’s important to do your first layer test to ensure quality print.

Step 3: Load the 3D design file (STL) into the 3D slicing software. Set up the printer settings and save the G-code file to a memory card. Then, put the card into the printer and load the file for printing. Advance printer will even have Bluetooth file sharing system.

Step 4: Now the printer will heat up and it will start printing.

NOTE: The thickness of each layer is measured in millimeters, and 3D print is made up of thousands of layers.

Popular 3D Printing Use Case:

Let’s talk about some amazing things 3D printing can do. It’s not just for making toys or gadgets. In medicine, doctors are trying out special materials to help with healing. They can use a person’s cells to 3D print things like ears and noses. Some surgeons have even tried 3D printed organs for transplants. In whole world now 3D printer house are getting popular too because it’s cost effective and fast to built it.