If you’re familiar with 3D printing, you’ll know that the choice of filament can make or break your project. Due to its unique properties, nylon filament has emerged as a popular choice for FDM 3D printers. It’s known for its strength, flexibility, and durability, making it a versatile material for a wide range of applications.

But what sets Nylon filament apart from the rest? Well, it’s all about the balance. Nylon strikes an impressive balance between flexibility and durability, a combination that’s hard to find in other filament materials. It’s resistant to wear, heat, and chemicals, making it ideal for creating parts that need to withstand tough conditions. Plus, its low friction coefficient makes it perfect for mechanical parts. So, whether you’re a hobbyist looking to experiment or a professional seeking the best material for your next project, Nylon filament in 3D printing could be your perfect choice.

Here in this article let’s learn more about Nylon filament in detail

Table Of Contents

Nylon Filament For 3D Printing:

Nylons belong to the family of synthetic polymers known as polyamides. These versatile polymers are composed of repeating units called amides, which are linked together through strong chemical bonds. As a result, Nylons possess exceptional strength, durability, and resistance to wear and tear, making them ideal to be used as a filament material for FDM 3D printer.

Now you know why Nylon filament is a versatile and highly durable material that’s often used in 3D printing. Due to these properties, it has become a popular choice for parts that need to withstand wear and tear.

Not only is nylon resistant to impact and abrasion, but it also has excellent heat resistance. This makes it ideal for printing parts that will be exposed to high temperatures.

Moreover, nylon isn’t just tough – it’s also flexible. This means it can be used to print parts that need to bend or flex during use, such as gears and hinges.

However, Nylon filament is also known for its high shrinkage rate, which can lead to warping if not properly managed. It also absorbs moisture from the air, which can affect the quality of your prints if not stored properly.

I will share both the pros and cons in detail next in this article.

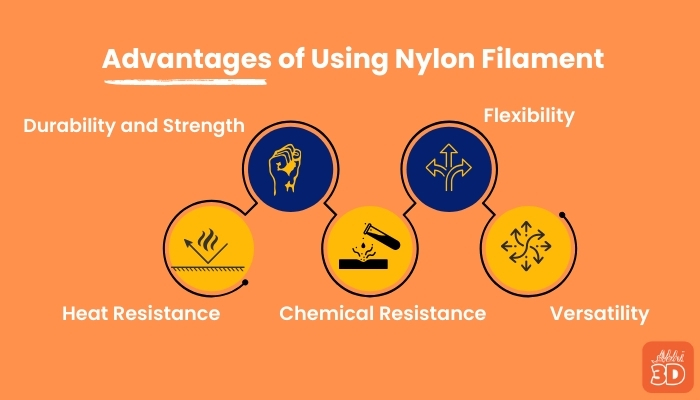

Advantages of Using Nylon Filament in 3D printing:

This Nylon filament material has been gaining popularity in the 3D printing community, and for good reason. Let’s break down the advantages step by step.

1. Durability and Strength:

Nylon filament is known for its impressive durability and strength. It’s a synthetic polymer that can withstand high levels of stress, making it ideal for creating parts that need to be tough and resilient.

2. Flexibility:

Unlike some other materials, nylon filament offers a degree of flexibility. This means it can be used to print objects that need to bend or flex without breaking, such as gears or hinges.

3. Heat Resistance:

This filament has a high melting point, which makes it a great choice for objects that will be exposed to high temperatures. This can be particularly useful in industries such as automotive or aerospace.

4. Chemical Resistance:

Another advantage of nylon filament is its resistance to chemicals. This makes it suitable for printing objects that will be exposed to various chemicals, such as containers or parts for machinery.

5. Versatility:

Finally, nylon filament is incredibly versatile. It can be used to print a wide range of objects, from functional parts to decorative items.

Let’s break down some negatives of Nylon Filament 3D printing.

Cons of Using Nylon Filament in 3D Printing:

- One of the main issues is its high moisture absorption. Nylon filament can absorb moisture from the air, which can lead to problems during the printing process. So it’s recommended you use an enclosed 3D printer.

- Another downside is nylon’s high printing temperature. Nylon requires a higher extruder temperature compared to other materials, usually between 240°C and 260°C.

- It’s warping and shrinkage is also kind of issue. This can make it difficult to print large objects or those with a large flat surface area.

- Nylon filament can be quite expensive compared to other materials like PLA or ABS. This cost factor can be a significant consideration for hobbyists or those on a tight budget.

Next, let’s see the printer setting of Nylon Filament 3D printing.

Nylon Filament Recommended 3D printer Settings:

1. Preheat Your Printer:

If you are using Nylon Filament it requires a higher extruder temperature, usually between 220°C and 260°C. Preheat your printer to the appropriate temperature for your specific nylon filament.

2. Adjust the Print Bed:

Nylon filament tends to warp, so it’s crucial to have a heated print bed. Set your print bed temperature to around 70°C to 100°C.

3. Load the Nylon Filament:

Once your printer is preheated, load the nylon filament into the extruder. Make sure the filament feeds smoothly into the machine.

4. Configure the Print Speed:

This is the best at a slow to moderate speed. Set your print speed to around 30-60mm/s to ensure the best quality print.

5. Test Print:

Before you start your main project, do a test print. This will help you adjust any settings if necessary.

Summary of Nylon 3D Printer Settings:

| Filament | Strength | Uses | Bed Temperature | Print Temperature | Special Properties | Flexibility | Durability |

|---|---|---|---|---|---|---|---|

| Nylon Filament | High | All | 70°C to 100°C | 220-260°C | Strong Durable Flexible | High | High |

Nylon Filament FAQ (Frequently Asked Questions)

Some of the most frequently asked questions about nylon filament in 3D printing.

Storing Nylon filament properly in an airtight container is crucial to maintain its quality and longevity. Start by keeping it in a cool, dry place, as nylon filament is hygroscopic, meaning it absorbs moisture from the air. This can lead to poor print quality and even damage your 3D printer.

To prevent this, store your nylon filament in an airtight container with desiccants to absorb any moisture. If your filament has already absorbed moisture, you can dry it out in an oven at a low temperature. Remember always to handle your filament with clean hands to avoid introducing oils or other contaminants that could affect your prints.

Using Nylon filament in 3D printing comes with its own set of challenges. First and foremost, nylon is highly sensitive to moisture, meaning it can absorb water from the air, which can lead to printing issues like poor layer adhesion and popping or bubbling during printing. It also tends to warp during cooling, making it challenging to print large objects or those with a large surface area on the print bed.

Conclusion:

In the end, I will say Nylon filament will be a great choice if you are looking for a material that offers high strength, flexibility, and resistance to wear and tear.

However, it does come with its own set of challenges, such as moisture absorption, difficulty in storage, and the need for a high printing temperature. Proper handling and storage can mitigate these issues, making nylon a valuable filament material in the world of 3D printing.