If you have recently bought a 3D printer or planning to buy a new one, you must have noticed almost all 3D printers now come with auto bed leveling.

Does that mean after you buy an FDM 3D printer with auto bed leveling, you don’t have to level the print bed at all? Auto bed leveling does it for you?

Well, the answer is no, and here in this article, I will help you understand auto bed leveling and why even after having auto bed leveling you still need to manually make adjustments to get the first layer printed nicely on your build plate.

But before we begin let’s see the definition of Auto Bed leveling.

Table Of Contents

What Is Auto Bed Leveling?

Auto Bed Leveling in 3D printing is a feature that automatically calibrates the distance between the print bed and the nozzle.

This automatic process helps to compensate for any unevenness or tilt in the print bed, ensuring that the first layer of the print adheres properly, which is crucial for the success of your 3D print.

This feature can greatly improve the ease of use and print reliability, especially for larger 3D printers.

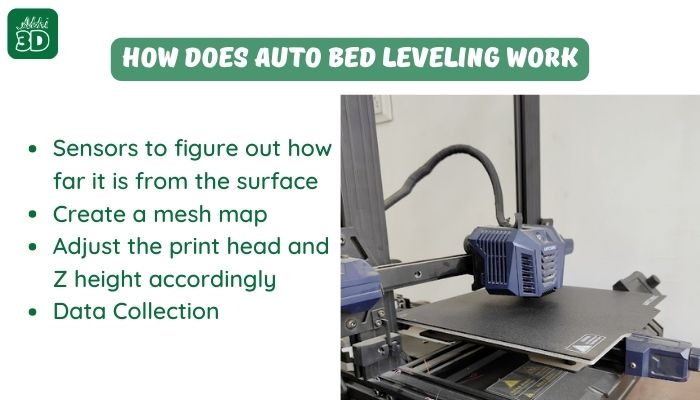

How Does Auto Bed Leveling Work?

You already know that even the slightest deviation or tilt can cause a print to fail, especially for larger prints. Auto bed leveling helps to prevent these issues.

Here’s how it works.

1. Sensors or Probe:

The Auto Bed leveling 3D printer has sensors or a tool attached to the part that puts out the ink. This tool can figure out how far it is from the surface where the printing happens.

2. Create a Mesh Map:

The printer then generates a mesh map of the bed’s surface, with values and coordinates representing the height differences between the print head and the print bed.

3. Adjust the print head:

Instead of adjusting the print bed manually, the printer moves the print head around to compensate for the leveling deviations of the print.

This can involve extruding more material in low spots to build them up or thinning out the material in high spots.

4. Adjusting Z height When the nozzle Moves:

The 3D printer software automatically makes small adjustments to the Z height as the nozzle moves, maintaining a consistent offset from the bed.

6. Data Collection:

The collected data is used to calculate the actual orientation of the print bed concerning the movement of the nozzle in the XY axes.

So that’s how auto bed leveling works.

But the thing is even after doing the auto bed leveling process you still need to manually level your print bed and set your Z offset. Let’s find out why.

Why Even After Using Auto Bed Leveling You Still Need To Make Manual Bed Level Adjustments?

Why Your 3D Printer Needs To Have Auto Bed Leveling?

1. Improved Print Quality: It helps in achieving a more accurate first layer, which is crucial for the overall quality of the print.

2. Time-Saving: Even though manual bed leveling might still be required, but having auto bed leveling makes the process faster and easier. Especially for beginners.

3. Increased Reliability: It reduces the chances of print failure due to an uneven print bed. Thus providing consistent results, regardless of the print size or complexity.

4. Ease of Use: It makes 3D printers more user-friendly, especially for beginners.

Auto Bed Leveling Vs Unified Bed Leveling:

Before we end this guide I want to cover one more topic which is especially for 3D tech enthusiasts.

It’s about ABL and UBL.

Full Form of ABL: Auto Bed Leveling

Full Form of UBL: Unified Bed Leveling

They both are two different methods of calibrating the print bed in 3D printing. Here are some differences between ABL and UBL.

| Auto Bed Leveling (ABL) | Unified Bed Leveling (UBL) |

|---|---|

| 1. Method of Operation: ABL is a simpler system that probes the bed in a grid and applies a mesh-based compensation for any deviations it finds. It’s a more straightforward process that doesn’t require as much user interaction. | 1. Method of Operation: UBL is a more comprehensive system that allows for more user control and customisation. It uses a mesh-based system like ABL, but it also allows for manual adjustment of the mesh points, which can be useful for dealing with more complex bed issues. |

| 2. Complexity: ABL is generally easier to set up and use, making it a good choice for beginners or for those who want a more ‘set it and forget it’ approach. | 2. Complexity: UBL, on the other hand, is more complex and can take more time to set up and fine-tune. However, it can also provide better results, particularly on beds with a lot of variation. |

| 3. Ease of Use: ABL is generally easier to set up and use, making it a good choice for beginners or printers with relatively flat beds. | 3. Ease of Use: UBL, while more complex to set up, offers more control and customisation, making it a good choice for advanced users or printers with more complex bed surfaces. |

| 4. Memory Usage: ABL can be a consideration if you are using a printer with limited memory. | 4. Memory Usage: UBL typically requires more memory due to the detailed mesh it creates. |

| 5. Flexibility: ABL does not have this feature. | 5. Flexibility: UBL allows for more flexibility as it allows you to manually adjust the mesh and save multiple meshes for different print conditions. |

Conclusion:

Auto Bed Leveling feature automatically calibrates the distance between the printer’s extruder and the print bed, ensuring a smooth, even surface for printing.

This process compensates for any unevenness or tilt in the bed, enhancing the quality and precision of the printed object.

Does your 3D printer have auto bed leveling feature? Let us know your experience using it in the comments below.