The print time is a crucial factor in 3D printing. Faster infill patterns can significantly reduce the time it takes to print an object, making the process more efficient and cost-effective.

Before discussing 5 fastest infill patterns let’s first understand the basics of infill pattern. The infill pattern refers to the internal structure of a printed object. It’s like the skeleton of your 3D print, providing strength and stability, while also saving on material and reducing print time.

Table Of Contents

Why Fastest Infill Is Important:

The printing time can significantly vary depending on the chosen infill pattern. So understanding the fastest infill pattern in 3D printing is important for various reasons:

– It allows for efficient use of materials, saving on costs and reducing waste.

– It can significantly reduce the printing time, making the process more efficient.

– It can also affect the strength and weight of the printed object, which can be critical depending on the application.

– By understanding this aspect, you can optimize your 3D printing process and create high-quality prints in less time and with less material.

5 Fastest Infill Patterns:

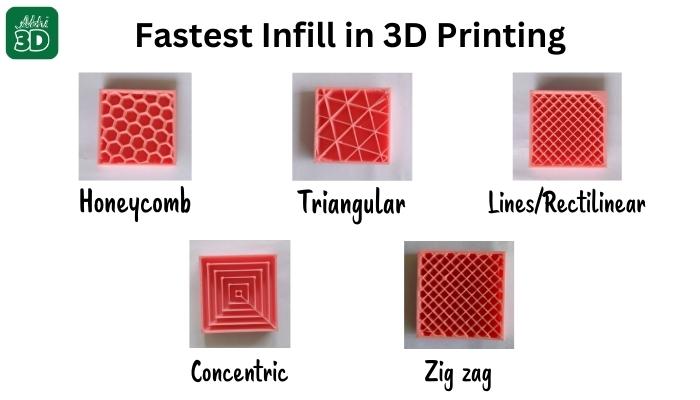

Now I will list out the 5 fastest infill patterns that you can consider. I’ll discuss their unique characteristics, advantages, and why they’re considered the quickest in the 3D printing world:

Lines And Rectilinear Infill:

The fastest infill pattern is considered to be a Rectilinear or Lines pattern. This pattern prints in simple straight lines, crossing over each other at right angles and creating a grid-like structure. This pattern is faster because it requires fewer movements and changes in direction compared to other patterns. Below you can see a cube inside with Rectilinear or Lines infill.

Pros: The Rectilinear pattern is not only fast but also efficient in terms of material usage. It provides a good balance between speed, strength, and material usage. It is ideal for prints where speed is a priority over the strength of the final object.

Cons: While Rectilinear is the fastest, it may not always be the best choice. It is not as strong as some other infill patterns, like the honeycomb or grid. It is best suited for objects that do not require high strength or durability.

The Triangular pattern is slightly slower than Rectilinear but offers more strength. It consists of a series of triangles, which is the strongest shape in construction. You must consider this pattern when you want a good balance between print speed and strength. Below you can see a cube printed with triangular infill.

Pros: Triangular infill is relatively quick to print and provides strong structure compared to other infill patterns, making it a good choice for various 3D projects. So, if you are looking for a good balance between print time, strength, and material consumption, you should consider using this pattern.

Cons: Compared to rectilinear infill patterns, triangular infill takes longer and more material to print. This is because the printer has to make more movements to create the intricate pattern of triangles.

The Honeycomb pattern is slower than Rectilinear and Triangular but offers the most strength. It consists of hexagons, copying the structure of a honeycomb. You can consider this pattern when strength is more important than print time. Below you can see a cube printed with honeycomb infill.

Pros: Honeycomb infill offers several advantages, providing a balance of increased strength, material efficiency, and faster print times. Using this infill, you could create a strong, durable prototype quickly and with less material.

Cons: Honeycomb pattern is more complex than other infill patterns, such as rectilinear or grid. This complexity means that your 3D printer will take slightly more time and material to complete the print.

The Concentric pattern is similar in speed to the Triangular pattern. It consists of concentric shapes, usually squares or circles, that follow the shape of the object. You can consider using this pattern when you want your 3D-printed objects to have strength in all directions.

Pros: Concentric pattern provides aesthetic appeal, smoother outer surfaces, reduced print time, and improved flexibility to your 3D printed objects.

Cons: Concentric infill is not as strong as other infill patterns like rectilinear or honeycomb. This is because the layers are not interlocked, but rather laid down in a circular pattern. You may not want to use this infill for printing those objects that require high strength and consistent infill density.

Zigzag Infill:

The Zigzag pattern is similar in speed to the Rectilinear pattern. It consists of a continuous line zigzagging back and forth. This pattern is quick to print and offers a good balance between speed and strength.

Pros: Zig Zag infill is ideal for models that require a balance between strength and print speed. It’s particularly useful for models that don’t need to hold heavy stress, but still require a certain level of durability.

Cons: It’s not the strongest infill pattern. For models that need to withstand high stress or load, other infill patterns like gyroid, grid or cubic might be more suitable.

Comparing Fastest Infill Pattern Using Cura and Prusa 3D Slicer:

Now first let’s do a test using Cura 3D slicer for all above 5 infill pattern and find out which infill pattern will take how much time. I will use a Cat STL file and slice it with 15% infill density.

After I sliced the Cat STL you can see below Concentric Infill is taking less time compared to all other infill. Even though it’s the fastest as per Cura slicing time but I will still not recommend it as it’s kind of the weakest of all. The inner square lines are not well attached to each other to give the enough strength needed. So I will still say consider using lines, rectilinear, or any other infill.

I did the same model test with Prusa slicer and below you can see the result. Here you can see rectilinear infill takes the lowest time compared to all other infill.

Important Note: From our experience, we can tell you that 3D slicer time and real print time when you actually print the object vary a bit. So take the above result as just an approximation of the result.