Triangular infill is a pattern used in 3D printing, which consists of numerous triangles. This pattern is known for its strength and efficiency. This pattern is used to fill up the inside of the object being printed. You can prefer this pattern when your printed object needs to withstand some level of stress or force.

Table Of Contents

What Is Triangular Infill?

Triangular Infill Settings In Cura:

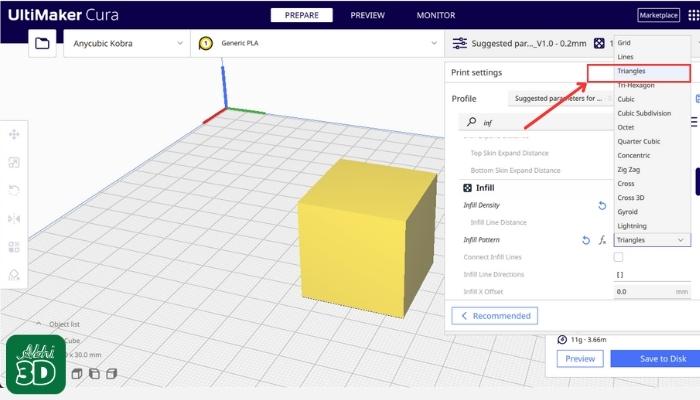

Triangular infill is a pattern used when 3D printing to fill the interior of an object with a triangular grid. Here’s a simple guide to set up triangular infill in Cura:

1. Open Cura: Open the Cura software on your computer. If you don’t have it installed, download and install it from the official website.

2. Import Your Model: Load the 3D model you want to print into Cura. You can do this by clicking on “Open File” or dragging and dropping the model into the Cura workspace.

3. Select Print Settings: On the right side of the Cura window, you’ll see a panel with various settings. Click on the “Custom” button to open the detailed settings.

4. Infill Settings: Look for the section labeled “Infill” or “Fill.” Here, you’ll find options related to the infill pattern.

5. Choose Triangular Infill: On the right side of the Cura window, you’ll see a panel with various settings. Click on the “Custom” button to open the detailed settings.

6. Adjust Infill Density: Set the infill density, which determines how much of the interior is filled with triangles. A higher percentage means a denser interior. You can usually adjust this with a slider or by typing in a percentage.

7. Slice Your Model & Save G-Code File: After adjusting the infill settings, click the “Slice” button. This process generates the G-code, which is the set of instructions your 3D printer will follow.

8. Print Your Model: Transfer the G-code file to your 3D printer and start the printing process. The printer will follow the triangular infill pattern according to the settings you specified.

Advantages of Triangular Infill pattern:

Prints Faster: Because it doesn’t fill everything up like a solid block, it takes less time to print. So, you get your 3D prints faster with the triangular infill.

Strength with Less Material: Triangles are strong shapes. When we fill the inside of a 3D-printed object with a triangular pattern, it stays strong but uses less material. So, your creations are sturdy without being too heavy or wasting material.

Saves Money: Less material and less time mean you spend less money on materials and electricity. It’s like being efficient and smart with your resources.

Weight Reduction: Triangular infill creates a lightweight internal structure, advantageous for applications where minimizing weight is crucial, without compromising the overall strength of the print.

Strong Foundations: Triangular infill provides a solid internal structure for 3D prints, distributing strength evenly through its geometric design.

Material Savings: By using less material, the triangular pattern reduces print time and costs, making it an efficient choice for resource-conscious 3D printing.

Lightweight Outcome: The pattern creates a lighter final product without sacrificing strength, ideal for applications where weight is a consideration.