If you’ve been doing 3D printing for some time now, you’re probably already familiar with various Filament types that are available in the market. Here in this guide, I will help you know about the carbon fiber filament.

Now, you might be wondering, “Why carbon fiber?” Well, the answer lies in its unique properties. Carbon fiber is well known for its high strength-to-weight ratio, which means 3D-printed objects created with it offer greater strength for their weight. It has many more advantages which I will discuss later in this guide.

Let’s start with what is carbon fiber filament.

Table Of Contents

What is Carbon Fiber Filament?

Carbon fiber filament is a composite material, made from a base material (usually PLA, ABS, or PETG) infused with tiny carbon fiber strands. This unique composition results in a filament that’s not only incredibly strong and lightweight but also has a distinct, professional finish that’s hard to achieve with other materials.

Engineers choose carbon fiber filament because of its versatility and strength-to-weight ratio. This filament is a favorite among those who use it to print parts that need to withstand significant stress or wear. For example, you can think of drone components, automotive parts, or even prosthetics.

However, Carbon filament is not all about strength. It also has excellent dimensional stability, meaning it doesn’t warp or shrink as much as other materials. This makes it a fantastic choice for printing large, complex parts. But remember, with great power comes great responsibility – or in this case, you will need a specialized printer and nozzle setup to use it.

3D Printing Tips For Carbon Fiber Filament:

If you are planning to use Carbon Fiber filament as your material to 3D print your designs make sure to follow below tips before you start.

1. Printer Compatibility:

Not all 3D printers are equipped to handle the rigors of carbon fiber filament. Ensure your printer has the necessary hardware to withstand the filament’s abrasive nature.

2. Hardened Steel or Ruby Nozzle:

Due to its abrasive nature, carbon fiber filament can wear down standard brass nozzles. So if you want to use it you should consider upgrading to a hardened steel or ruby nozzle for better durability.

3. Bed Adhesion:

Carbon fiber filament can be tricky when it comes to bed adhesion. I will recommend you use a heated bed and adhesion aids like glue stick or hairspray can help.

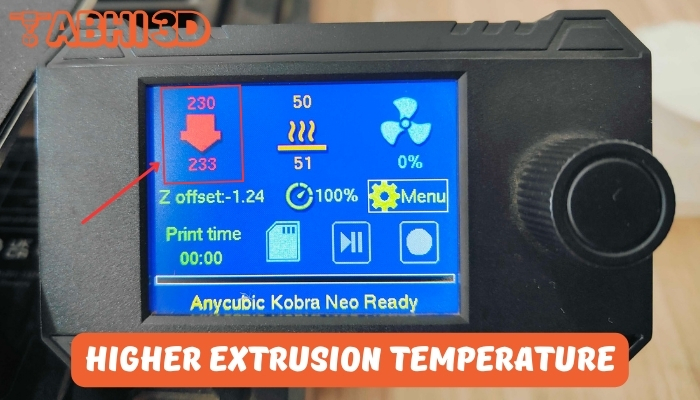

4. Temperature Settings:

Carbon fiber filament often requires higher extrusion temperatures. The best way is to begin with the recommended settings as mentioned on the filament packaging and adjust as needed. A nozzle temperature range of 230°C to 260°C is commonly recommended for printing with carbon fiber filament. And bed temperature in the range of 50°C to 70°C is often suitable for printing with it.

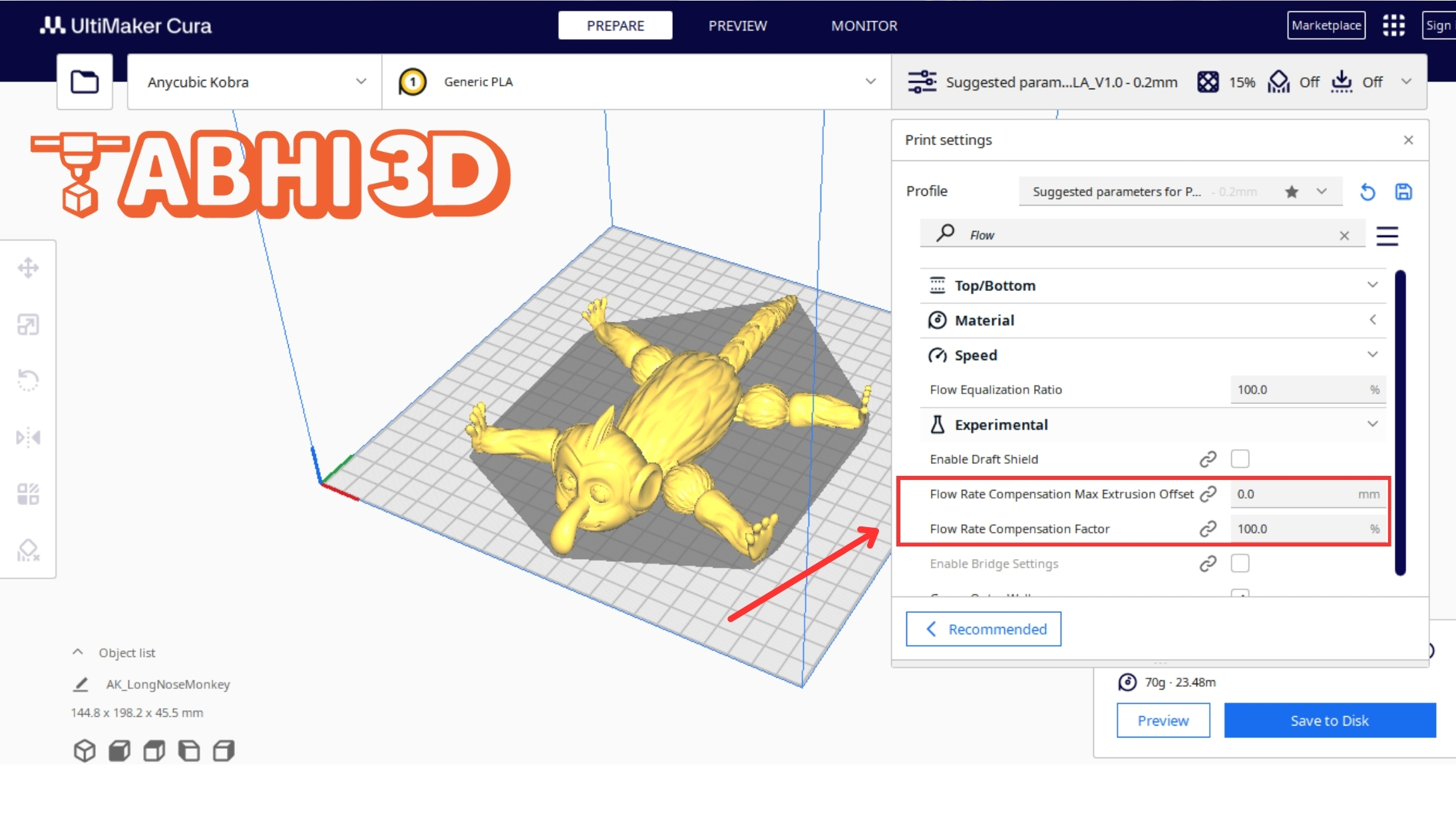

5. Layer Adhesion:

If you are facing an issue with first-layer Bed adhesion using Carbon fiber filament you might want to consider using extrusion multiplier setting. For those not aware, an Extrusion multiplier also known as a flow rate or flow multiplier. It is a setting used in 3D printing software to adjust the amount of material extruded from the printer’s nozzle. It is typically expressed as a percentage, where 100% represents the default extrusion rate determined by the slicer software based on the filament diameter, layer height, and nozzle size.

If you are facing layer adhesion when printing with Carbon Filament, consider increasing the extrusion multiplier. This can help ensure a stronger, more durable print.

6. Post-Processing:

Carbon fiber prints can be sanded and painted for a more polished finish. However, be aware that sanding can release small particles, so always use proper safety equipment.

Advantages of Using Carbon Fiber Filament:

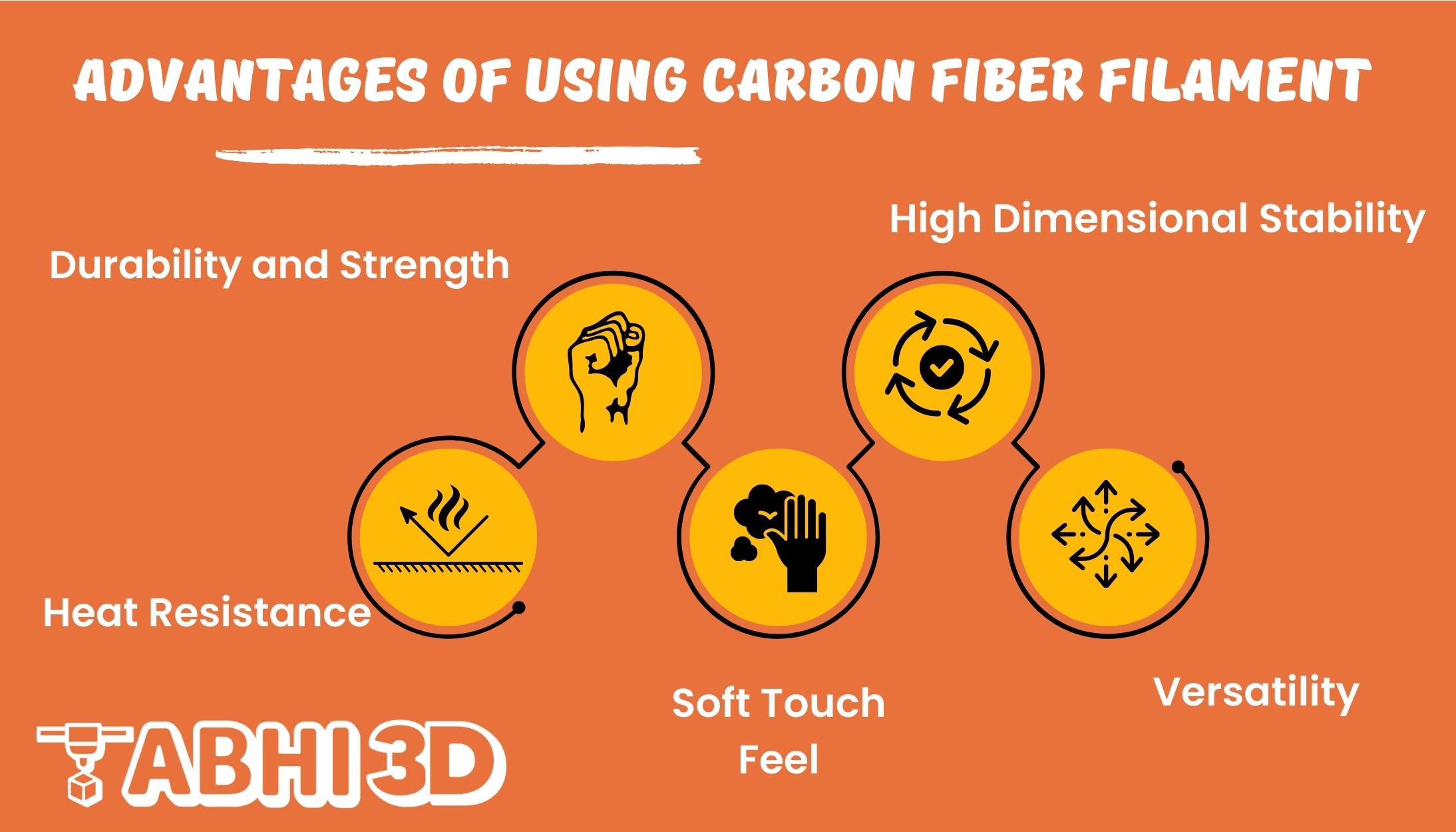

The advantages of carbon fiber filament often outweigh some of the challenges as discussed earlier. Its strength, lightness, and durability make it an excellent choice for high-performance parts. Let’s see it’s advantages.

1. Strength and Durability:

Carbon fiber filament is renowned for its impressive strength-to-weight ratio. This makes it an ideal choice for applications that require both lightness and durability.

2. High Dimensional Stability:

Unlike some other materials, carbon fiber filament doesn’t warp or shrink during the printing process. This ensures a high level of precision in the final product.

3. Heat Resistance:

This filament can withstand high temperatures, making it suitable for applications that involve heat exposure.

4. Versatility:

Carbon fiber filament can be used to print a wide range of items, from prototypes and tools to intricate art pieces.

5. Low Thermal Expansion:

Carbon fiber has low thermal expansion properties, meaning it retains its shape and dimensions even under extreme temperature changes, reducing the risk of warping or deformation.

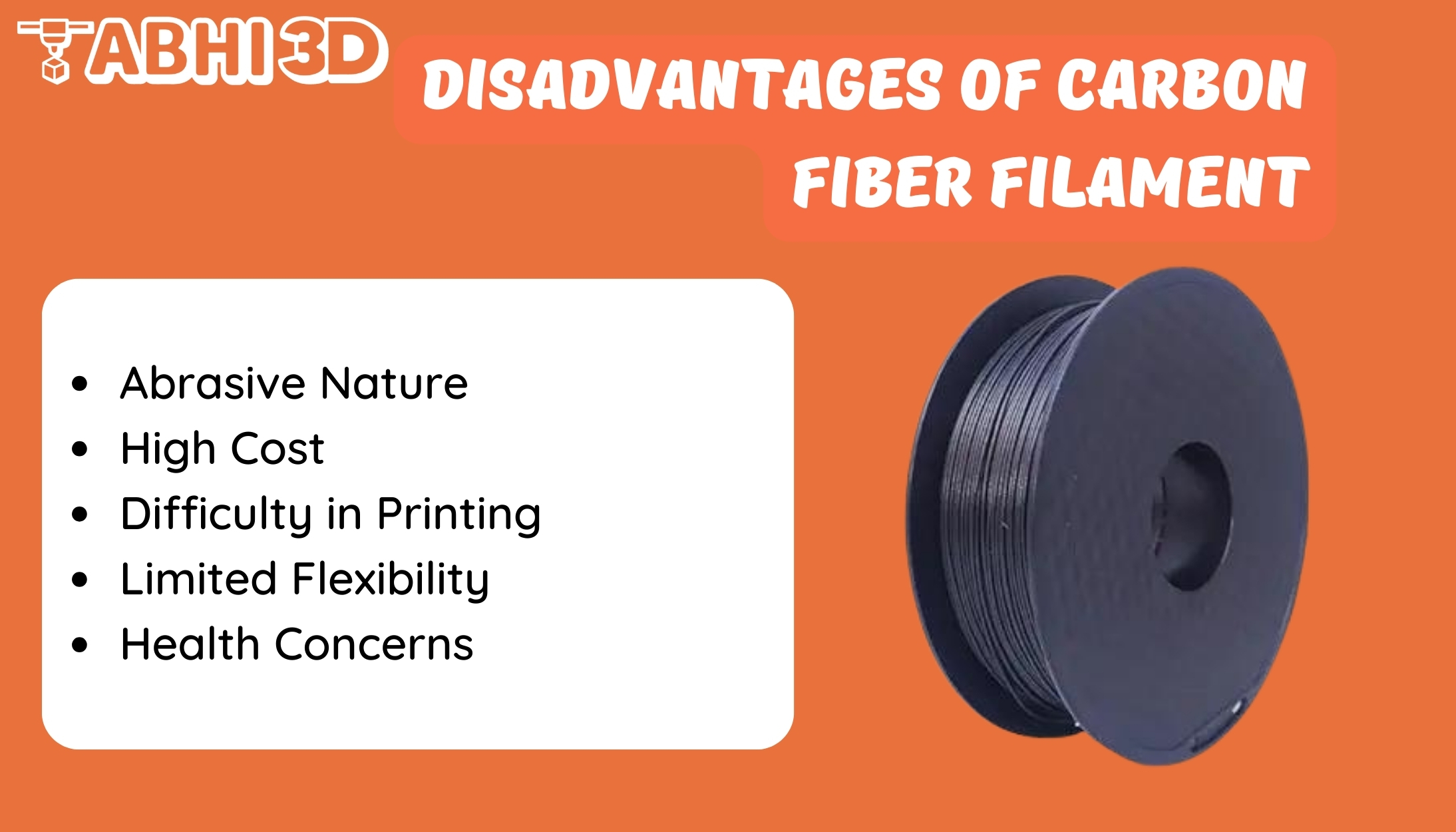

Disadvantages of Carbon Fiber Filament:

Now let’s look at the downside of using Carbon Fiber filament for 3D printing objects.

1. Abrasive Nature:

Carbon fiber filament is known for its abrasive nature. This means it can cause significant wear and tear on the standard brass nozzles of 3D printers. So you will need to invest in a higher-cost Nozzle like Ruby nozzle.

2. High Cost:

Compared to standard filaments like PLA or ABS, carbon fiber filament is significantly more expensive. For a 1KG spool, you can expect to cost around $25-$100.

This can make it a less viable option for hobbyists or small businesses operating on a tight budget.

3. Difficulty in Printing:

Carbon fiber filament can be challenging to print with. It requires precise temperature control and can be prone to warping or curling if not done correctly. I will recommend you keep a close eye on your first few layers and make sure they are getting perfectly laid on a printed bed.

4. Limited Flexibility:

While carbon fiber filament is incredibly strong and rigid, it lacks the flexibility of other filaments. This can limit its use in applications that require a degree of flexibility.

5. Health Concerns:

When heated, carbon fiber filament can release tiny particles into the air. If inhaled, these particles can pose a health risk. Therefore, it’s essential to use proper ventilation when printing with this material.

6. Limited Colors Option:

When it comes to carbon fiber filament, the most common color option available is black. This color is popular due to its sleek and professional appearance. While there are some limited color options available for carbon fiber filament, such as gray or dark blue, the choices are not as extensive as other types of filaments like PLA.

Carbon Fiber Filament FAQ:

Carbon fiber filament is generally stronger than PLA. This is because carbon fiber filament is a composite material, meaning it is made of two or more different materials that, when combined, produce a material with different characteristics. In the case of carbon fiber filament, the material is typically a blend of PLA and tiny fiber of carbon.

These carbon fiber give the filament a significantly higher strength-to-weight ratio, making it stronger and more rigid than standard PLA.

Carbon fiber filament exceptional strength is attributed to the carbon fiber embedded within the filament.These fiber, known for their high rigidity, tensile strength, and low weight, significantly enhance the filament’s durability and resistance to deformation under stress. The result is a filament that can withstand high pressure and wear, making it ideal for creating robust, high-performance parts.

Conclusion:

In conclusion, carbon fiber filament is known for its exceptional strength compared to other popular filaments on the market. If you are looking to create printed objects that can withstand high levels of stress and pressure, carbon fiber filament is a great choice to consider.

When it comes to choosing the right filament for your projects, it’s important to consider the specific requirements and demands of your designs. Carbon fiber filament stands out as a strong and reliable option for those looking to create durable and high-stress resistant objects. With its impressive strength and performance capabilities, carbon fiber filament is a top choice for those seeking quality and longevity in their 3D printed products.