Originally, filaments like PLA and ABS dominated the 3D printing. But a new addition to the list that is becoming popular is ASA filament.

You can think of ASA as ABS’s tougher cousin. It’s got all the benefits of ABS – like high impact resistance and flexibility – but it’s also UV resistant. So, in this situation, where you need a tough, weather-resistant material, ASA is your go-to filament.

For example, if you’re creating an outdoor sign or a drone part. You’d need a material that’s UV resistant and durable, right? That’s where ASA filament comes into play.

In this post, I’ll try to explain everything about ASA filament. I’ll cover benefits and, more importantly, its 3D printer settings. With this guide, you will be able to print using ASA filament like a pro.

Full Form of ASA: Acrylonitrile Styrene Acrylate

Table Of Contents

What Is ASA Filament?

ASA, or Acrylonitrile Styrene Acrylate, is a type of thermoplastic that’s known for its exceptional resistance to weather, UV light, and heat.

Let’s say you’ve got a project that requires a 3D-printed part to be exposed to the sun for long periods. Using PLA or ABS might result in warping or discoloration.

So what happens if you’ve got ASA filament at your disposal? Well, ASA’s UV resistance ensures that your print maintains its shape and color, even under the harshest sunlight.

Now, you know why ASA filament is becoming increasingly popular, right? But remember ASA prints at a higher temperature than PLA or ABS, so you’ll need a 3D printer that can handle the heat. I will cover that later in our next topic.

ASA Filament 3D Printer Settings:

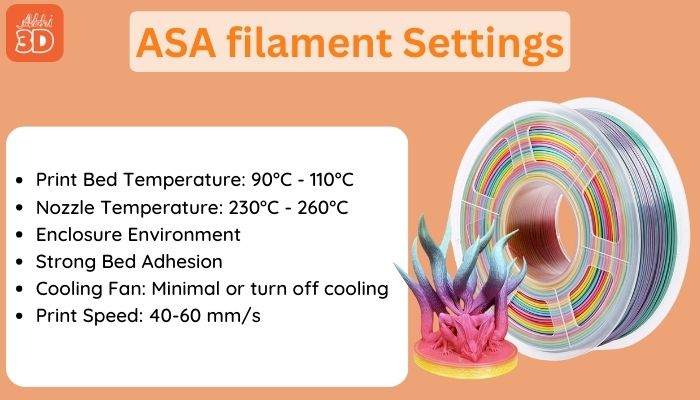

When setting up your 3D printer to use ASA filament, it’s important to adjust the printer’s settings to ensure optimal print quality.

This includes adjusting the nozzle temperature, bed temperature, print speed, and cooling settings.

These are the specific settings for ASA Filament.

1. Print Bed Temperature:

The bed temperature plays a pivotal role in ensuring the first layer of your print adheres properly to the build plate. For ASA filament, the recommended bed temperature typically ranges from 90°C-110°C (194°F – 230°F). This range helps to prevent warping and ensures a smooth, high-quality print.

However, remember that these are just guidelines. Depending on your specific 3D printer model and the environmental conditions, you might need to tweak these settings a bit. So, don’t be afraid to experiment and find the sweet spot that works best for you.

2. Nozzle Temperature:

When it comes to ASA filament, the nozzle temperature is a critical factor that can make or break your 3D printing experience. Typically, the ideal temperature range for ASA filament lies between 230°C-250°C (466°F – 500°F).

Now, you might be wondering, “Why such a high temperature?”

Well, ASA, or Acrylonitrile Styrene Acrylate, is a robust material known for its exceptional thermal stability, which means it requires a higher temperature to melt and form into your desired 3D model.

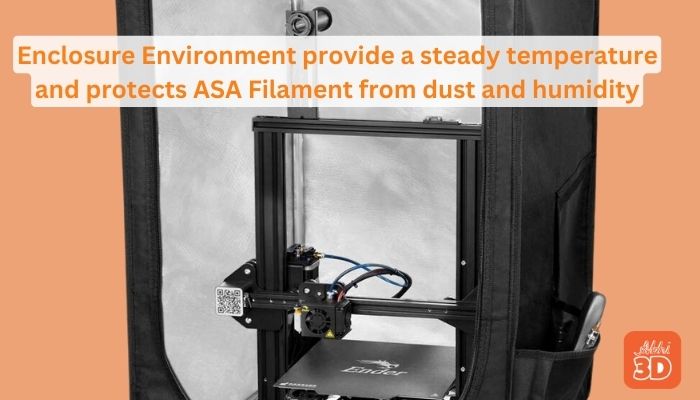

3. Enclosure Environment :

When it comes to 3D printing with ASA filament, the enclosure environment is a critical factor to consider.

It’s not just about keeping the temperature steady, oh no, it’s about creating a controlled environment that ensures the ASA filament performs at its peak.

This enclosure environment maintains a consistent temperature, preventing the filament from cooling too quickly and causing warping or cracking. It’s like a warm blanket on a cold winter’s night, providing the filament with the comfort it needs to deliver the best results.

But it’s not just about temperature. The enclosure environment also protects the filament from external factors like dust and humidity, which can affect the quality of the print.

4. Bed Adhesion:

ASA filament, known for its exceptional UV resistance and mechanical strength, can be a bit tricky to work with due to its high printing temperature. But don’t worry, I’ve got you covered.

Firstly, ensure your print bed is squeaky clean. Any dust or grease can interfere with adhesion.

Secondly, consider using a heated bed. We all-ready shared ASA filament loves a warm bed, ideally around 100°C. This helps the first layer of filament to stick properly and prevents warping.

Lastly, don’t forget about using adhesion helpers like glue sticks, hairspray, or specialised 3D printing adhesion sprays. They can be your good friends in this process if you are facing warping issues.

5. Cooling Fan:

One crucial aspect often overlooked is cooling. It is a critical factor in 3D printing with ASA filament. It affects the quality of the print, the strength of the model, and even the success of the print job itself.

This filament requires minimal cooling. Too much cooling can cause the print to warp or crack. It’s best to turn off or minimize the cooling fan.

6. Print Speed:

What is the ideal print speed for ASA filament? A print speed of 40-60 mm/s is suitable for most ASA prints. Slower speeds may be required for intricate or complex designs. If you print too fast, you may encounter problems such as poor layer adhesion, extruder skipping, or stringing.

You can start with a print speed of around 40 mm/s and adjust as necessary based on your results.

Benefits And Negative Of Using ASA Filament:

Using ASA filament as your 3D printing material will create objects with high-impact resistance and flexibility. Not only that these printed objects also have excellent weather-resistant characteristics compared to other filaments like PLA or ABS.

Key benefits of ASA filament include:

- ASA filament is known for its exceptional resistance to UV rays and weather conditions. This makes it an ideal choice for outdoor applications.

- This filament can withstand high temperatures without deforming or melting, making it perfect for printing objects that will be exposed to heat.

- With its robust mechanical properties, ASA filament can produce prints that are not only aesthetically pleasing but also structurally sound.

- From automotive parts to outdoor signage, you can use ASA filament for a wide range of applications.

- These filament create prints with a smooth, glossy finish, enhancing the visual appeal of the final product.

Some negatives of ASA filament include:

- ASA filament requires a high extrusion temperature, typically between 230-250°C (466°F and 482°F). This can be challenging for beginners or those with less advanced 3D printers.

- It can release harmful fumes during the printing process. Therefore, it’s essential to use it in a well-ventilated area or have a printer with a good filtration system.

- One of the main disadvantages is its cost. ASA filament is generally more expensive than other common 3D printing materials like PLA or ABS, Which can make it a less economical choice for large-scale or frequent printing projects.

ASA Filament FAQ(Frequently Asked Question):

ASA filament like many other 3D printing materials should be stored in a cool, dry place away from direct sunlight.

It’s also recommended to keep it in a sealed container or bag with desiccants to prevent moisture absorption, as this can affect the quality of the prints and performance.

Additionally, it should be kept away from heat sources as it has a high glass transition temperature.

If the filament does absorb moisture, it can be dried in an oven at a low temperature, but care must be taken not to overheat and deform the filament.

Well, first off, ASA Filament incredibly durable. It’s known for its high impact resistance, which means your printed objects won’t crack or break easily. This makes it perfect for functional parts or outdoor applications.

Moreover, ASA is UV resistant. Unlike other materials that might fade or become brittle over time when exposed to sunlight, ASA maintains its color and strength. It’s also got great thermal stability, so it can withstand high temperatures. So, if you’re looking for a material that offers durability, UV resistance, and thermal stability, ASA is your go-to choice.

In Conclusion:

ASA is often used for outdoor applications, such as car parts, toys, and structural components, due to its durability and resistance to UV rays and harsh weather conditions.

Compared to ABS, ASA is slightly easier to print, but it still shares some of ABS’s printing challenges, such as warping and the release of potentially hazardous fumes during printing.

To print successfully with ASA, it’s crucial to ensure proper bed adhesion, print at the correct temperature, and address potential issues like warping and poor surface quality.

Have you used ASA filament? Let us know your experience in comments below.