In this article, we discuss about the Resin liquid which is used as a printing material for resin 3d printers. This article is handy for those people who use resin-liquid for 3D printers.

First, I’d like to start with basic details about resin liquid.

Table Of Contents

What Is Resin Liquid Used In Resin 3D Printer?

Well, let me tell you, Resin is not just any liquid, it’s the magic potion that brings your 3D designs to life!

Haha. It might be a bad joke, but let’s get technical.

Resin liquid for 3D printing is a photopolymer that hardens under UV light. It’s like the Incredible Hulk of liquids, transforming from a simple liquid to a solid structure when exposed to UV light.

It uses Stereolithography (SLA) technology under which a high-powered laser is used to harden the liquid resin, layer by layer, to create a solid 3D object.

But what makes it so special? Why not just stick with the traditional filament?

Actually, Resin liquid provides a higher level of detail and a smoother finish than traditional filament. Don’t worry, I will compare both 3D printing material in detail later in this guide.

Next, let us discuss the Resin Liquid material types.

Resin Liquid Material Types:

Now, you might be thinking, there are different types of resin liquids available in the market, each with its unique properties. Let’s discuss some of the popular ones below:

1. Standard Resin Liquid:

Standard resin is perfect for general applications, producing high-detail, smooth finish objects. It’s commonly used for prototyping, model making, and product design.

However, it’s not as durable or heat-resistant as other specialty resins. So it’s not recommended for mechanical parts or items that will be exposed to high temperatures or stress.

2. Tough Resin Liquid:

Tough Resin is designed to simulate the feel and functionality of ABS plastic, a common material used in FDM 3D printers. This type of resin is known for its high durability and resistance to stress, making it an ideal choice for parts that will be subjected to high stress or strain, such as functional prototypes and mechanical parts.

It’s also known for its high detail resolution, making it a popular choice for parts that require intricate details. It’s also a great material for printing snap-fit joints or assemblies due to its flexibility and strength.

3. Flexible Resin Liquid:

Flexible resin material offers a unique blend of flexibility and strength that’s hard to find in other resin liquids. This resin creates highly detailed, intricate designs that are not only visually stunning but also durable and resilient.

The flexibility of this resin allows for a wider range of applications, including the creation of prototypes, models, and even functional parts.

4. Cast-able Resin Liquid:

Cast-able resin, when used in a 3D printer, transforms into a solid form that can be easily cast into metal. It’s a go-to choice for jewelers, dentists, and designers who crave precision and a high-quality finish.

Next, let’s understand some differences between Resin liquid and filament.

Difference Between Resin liquid and Filament:

Filament is used as printing material in popular FDM 3D printers and resin liquid in resin printers. Below let’s see its comparison against Resin liquid.

| Resin Liquid | Filament | |

|---|---|---|

| The Nature of the Materials | Resin is a liquid photopolymer that hardens when exposed to a certain wavelength of light. In SLA and DLP printers, a light source is used to selectively harden layers of the resin to form the 3D object. | Filament is a thermoplastic thread-like material that comes in spools. It’s heated until it melts and then extruded through a nozzle to create 3D objects layer by layer. |

| Quality and Precision | The printers can generally produce higher resolution and more detailed prints than filament-based printers. This is because the light source can be controlled more precisely than the extrusion of melted filament. | These printers are typically faster and more economical for larger, less detailed prints. |

| Material Properties | That’s often more brittle but can produce parts with a smoother surface finish and finer details, making it ideal for aesthetic models or prototypes. | Filament materials, such as PLA and ABS, are known for their strength and durability, making them suitable for functional parts. |

| Post Processing | When you use resin it requires washing in a solvent to remove excess resin, and then curing under UV light to fully harden the material. | Post-processing for filament prints may involve removing support structures and smoothing the surface with sanding or other techniques. |

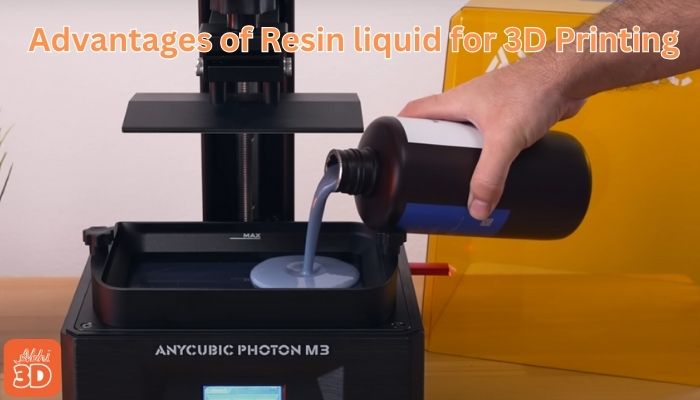

Advantages of Resin liquid for 3D Printing:

Let’s look into the key advantages of using resin liquid for 3D printing.

- Resin liquid for 3D printing allows you to create highly detailed and intricate designs. It’s like the difference between a high-definition TV and an old analog set. You’ll see every tiny detail clearly on your 3D object.

- Unlike other 3D printing materials, resin provides a smooth, almost glossy finish.

- This liquid offers high precision and accuracy, making it ideal for intricate designs and applications.

- Resin liquid comes in a variety of types, each with its own unique properties. Whether you need a flexible, tough, or high-temperature-resistant print, there’s a resin liquid for that.

Next, let us break down some disadvantages of using resin liquid.

Disadvantages of Resin liquid for 3D Printing:

- Resin prints require more post-processing. After a print is completed, it needs to be cleaned and cured. This can be a messy process and requires additional equipment.

- While filament printers can use a wide variety of materials, resin printers are limited to the types of resin they can use. This can limit the functionality and appearance of the final print.

- If you use resin liquid it can be messy and potentially hazardous to handle. It’s important to use gloves and work in a well-ventilated area to avoid exposure to harmful fumes.

- It takes more time than Filament. It’s not faster than filament.

How to Choose Right Resin Liquid for 3D Printer:

Well, are you looking to buy Resin liquid? Here I will suggest some factors that you should look at before making the purchase.

1. Research Resin Types:

Start first by researching the different types of resin. Standard resin is a good all-rounder, but if you need more strength, consider tough resin. For high detail, look at cast-able or flexible resins.

2. Consider Your Budget:

Resin can vary in price, so it’s important to factor in your budget. Remember, the most expensive resin isn’t always the best for your project. The usual cost of 1KG Resin liquid is somewhere between $15 – $100.

3. Check Printer Compatibility:

You must look at compatible resin for your resin 3D printers. It’s always good to check the manufacturer’s recommendations before purchasing.

4. Read Reviews:

Finally, read reviews from other users. They can provide valuable insights into the performance and reliability of the resin.

Do you use Resin liquid? Let us know your experience in the comments below.