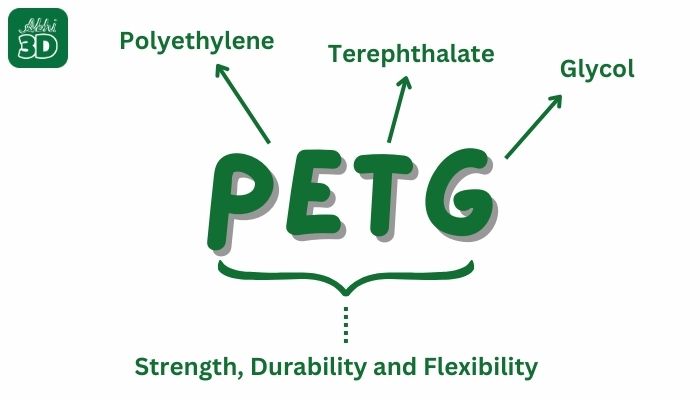

PETG filament is a type of 3D printing filament that stands for polyethylene terephthalate glycol and it is known for its durability and flexibility. It is commonly used for 3D printing objects that require strength, heat and impact resistance.

Table Of Contents

What Is ‘PETG’ In PETG Filament:

PETG stands for Polyethylene Terephthalate Glycol. It is a type of copolyester that shares properties of both PLA and ABS. PETG is known for its resilience and is often used for functional parts in 3D printing. It has a good mix of properties, making it a popular choice for 3D printing enthusiasts. Unlike PLA, PETG has a higher glass transition temperature, making it more suitable for applications that require heat resistance. It is also less demanding to print with than materials like nylon or polycarbonate. Various manufacturers have their own brand names for PETG, but it is essentially a glycol-modified version of polyethylene terephthalate.

Full Form of PETG: Polyethylene Terephthalate Glycol

Polyethylene: Polyethylene in PETG is used to enhance the filament’s durability, flexibility, and heat resistance. It also contributes to PETG’s ease of use in 3D printing, as it helps the filament adhere better to the print bed and reduces warping issues.

Terephthalate: Terephthalate in PETG is used to provide rigidity and chemical resistance. It’s the component that makes PETG a strong and durable material suitable for various applications, including 3D printing.

Glycol: Glycol in PETG is used to make the filament more flexible and prevent brittleness, enhancing its overall durability.

Benefits And Qualities Of Using PETG Filament In 3D Printing:

PETG filament is valued for its versatility, heat, and impact resistance, ease of use, and suitability for functional and structural prints, making it a popular choice for 3D printing professionals.

Let’s break down the qualities of PETG Filament one by one:

1. Easy to Use: PETG is easier to print with than ABS because it doesn’t warp as much. This means that the printed object stays the shape you want it to be.

2. Recyclable: PETG is recyclable, which is a big plus for environmentally conscious users. This means that items printed with PETG can be recycled, which is good for the environment.

3. Strength: PETG is very strong when compared it’s strength with other filament like PLA. It’s more flexible than PLA and more durable than ABS. This makes it great for printing objects that need to withstand a lot of wear and tear.

4. Good Finish: PETG prints have a glossy finish, which many people find attractive.

5. Flexibility: PETG Filament is like a strong rubber band. It’s tough and doesn’t snap easily. Plus, it can twist and bend a lot without cracking, which is great for making things that aren’t just straight lines.

6. Durability: PETG Filament is hard to break easily and can handle a lot of rough treatment. This makes it perfect for making things that need to be strong and long-lasting.

7. Clarity: PETG is like a clear glass. It’s more see-through than other materials, which can be a good thing for some projects where you want to add interior aesthetics.

8. Food Safe: PETG is generally considered safe for food contact, which makes it a good choice for printing items like cookie cutters or other kitchen tools.

9. Temperature Resistance: It has a higher melting point than PLA, making it suitable for objects that will be exposed to heat.

Cons of Using PETG Filament:

Let’s look at some PETG disadvantages that should be taken into account when considering the use of PETG filament for 3D printing, and appropriate measures should be taken to address these challenges for successful printing.

1. Difficulty in Printing: PETG can be more difficult to print with than other filaments like PLA. It requires fine-tuning printer settings for optimal results.

2. Stringing: PETG is prone to stringing or oozing during the printing process, which can affect the final print quality.

3. Requires Enclosed Printer: PETG often requires an enclosed printer to maintain a consistent temperature, which not all 3D printers have.

4. Sensitivity to Scratches: Although PETG is durable, it’s more prone to scratches compared to other materials.

5. Absorbs Moisture: PETG can absorb moisture from the air, which can affect the quality of the print and the lifespan of the filament.

Comparing PETG To PLA Filament:

PETG and PLA are both popular filaments used in 3D printing, but they differ in several ways. PETG handles stress well. On the other hand, PLA is biodegradable, easier to print with, and has a lower printing temperature. PLA is often used for decorative items, prototypes, and low-stress applications.

PETG Vs PLA Filament:

Now let’s look at comparison side by side.

|

PETG Filament |

PLA Filament |

|---|---|

| PETG is a variant of PET (Polyethylene Terephthalate), which is commonly used to make water bottles. | PLA (Polylactic Acid) is a biodegradable thermoplastic derived from renewable resources like corn starch or sugarcane. |

| PETG is not biodegradable, but it is recyclable. | PLA is biodegradable. So it’s environmentally friendly. |

| PETG requires higher printing temperatures and is less prone to warping compared to PLA. It is typically printed at nozzle temperatures ranging from 230-250°C. | PLA is easier to print with and generally requires lower printing temperatures compared to PETG. It has good flow properties and can be printed at a lower nozzle temperature, typically around 180-220°C. |

| PETG exhibits higher impact resistance and flexibility compared to PLA. It is less brittle and can withstand bending and torsional stress better than PLA. | PLA is more rigid and can be brittle, especially in thin or small printed parts. It is suitable for applications where rigidity and precision are important. |

Comparing PETG To ABS Filament:

PETG is known for its durability and ease of use, while ABS, is recognized for its high-temperature resistance and strength. The choice between the two often depends on the specific requirements of the 3D printing project.

Now let’s compare PETG to ABS filament and see how both stand out.

| PETG Filament | ABS Filament |

|---|---|

| Material Composition: PETG (Polyethylene Terephthalate Glycol) is a glycol-modified version of PET, known for its durability, transparency, and chemical resistance. It is often used for mechanical parts, food containers, and medical devices. | Material Composition: ABS (Acrylonitrile Butadiene Styrene) is a petroleum-based thermoplastic known for its strength, flexibility, and impact resistance. It is commonly used in the production of automotive parts, electronic housings, and toys. |

| Mechanical Properties: PETG offers good impact resistance and is more flexible than ABS, making it suitable for applications that require durability and transparency. | Mechanical Properties: ABS may not be as strong as PETG but exhibits high impact resistance and is more suitable for applications that require toughness and resilience to high temperatures. |

| Printing Parameters: PETG requires printing temperatures of around 230-250°C, and does not always require a heated bed, although a heated bed can still be beneficial for adhesion and reducing the risk of warping. | Printing Parameters: ABS typically requires the same printing temperature around 220-250°C, and a heated print bed to prevent warping and ensure adhesion. |

| Post-Processing: PETG is more resistant to chemicals and can be polished to achieve a transparent finish. It is less prone to warping and does not release toxic fumes during printing, unlike ABS. | Post-Processing: ABS on the other side can be sanded, glued, and painted more easily than PETG. It can also be smoothed with acetone vapor to achieve a glossy finish. |

PETG FIlament Recommended 3D Printer Setting:

To set up your 3D printer for PETG filament, follow these recommended 3D printer settings:

1. Print Bed Temperature: PETG prints best at a bed temperature between 70 and 90 degrees Celsius.

2. Extruder Temperature. PETG typically prints at a temperature between 220 and 250 degrees Celsius.

3. Cooling: Unlike PLA, PETG does not require active cooling during printing. It’s often recommended to disable or minimize the cooling fan to prevent rapid cooling and potential warping of the printed layers.

4. Retraction: Retraction settings may need to be adjusted when printing with PETG to minimize stringing and oozing. A retraction distance of around 1-3 mm and a retraction speed of 20-40 mm/s are common starting points

5. Layer Height and Adhesion: A layer height of 0.2-0.3 mm is often recommended for PETG. Additionally, ensuring proper bed leveling and initial layer adhesion is crucial for successful prints.

6. Extruder Settings: It’s important to ensure that the extruder is properly calibrated and that the filament is feeding smoothly to prevent under- or over-extrusion, which can affect print quality.

PETG Frequently Asked Questions (FAQs):

PETG Filament is a durable, flexible 3D printing material. It’s made from PETG plastic, which is known for its durability, flexibility, and heat resistance. Let’s now check some FAQs related to PETG filament.

What is PETG Filament made of?

PETG Filament is made from Polyethylene Terephthalate Glycol-modified (PETG), a type of plastic.

How to print with PETG Filament?

PETG Filament requires a heated print bed and extruder temperatures between 220°C and 250°C. It’s also recommended to print slower for better results.

Is PETG Filament safe?

Yes, PETG Filament is considered safe for 3D printing. However, it’s always recommended to print in a well-ventilated area.

Can PETG Filament be recycled?

Yes, PETG Filament is recyclable. However, not all recycling facilities accept it, so it’s best to check with your local facility.

If you have some other questions, please ask us in the comments below.