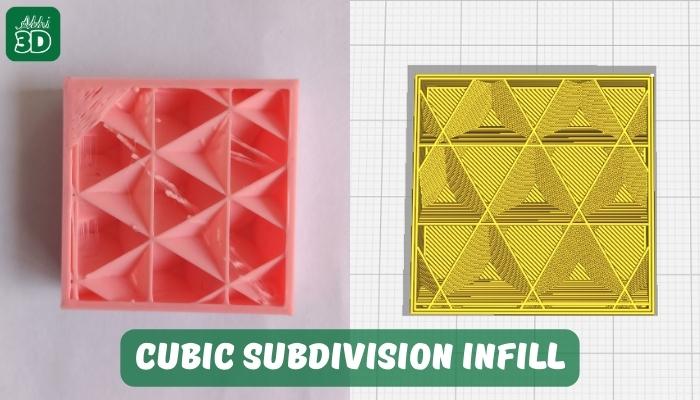

Cubic subdivision infill is a 3D pattern that subdivides the print’s interior into small cubes. This pattern provides excellent strength in all directions and uses less material than other infill types.

Cubic subdivision infill is a great choice for objects that need to be strong but lightweight. It’s also efficient, as it uses less material and reduces print time compared to other infill patterns. Cubic subdivision infill is ideal for applications where strength is needed in multiple directions. Examples include mechanical parts, drone components, and functional prototypes.

Table Of Contents

How To Enable Cubic Subdivision Infill Settings On Cura:

Enabling Cubic Subdivision infill settings in Cura, a popular 3D printing slicing software, is a straightforward process. Here’s a step-by-step guide on how to do it:

1. Launch the Cura software on your computer.

2. If you haven’t already, import the 3D model you want to print by clicking on “Open File” or dragging and dropping the STL file into the Cura workspace.

3. Click on the “Print Setup” tab in the left panel. This is where you can configure the printing settings, including infill patterns.

5. Configure Infill Settings:

a. Infill Density: Under the “Infill” section, you’ll see a slider for “Infill Density.” Adjust the percentage to set the density of the Cubic Subdivision infill. Higher values mean a denser infill, while lower values result in a sparser infill.

b. Infill Pattern: Just below the infill density slider, you can choose the infill pattern. Click on the dropdown menu, and you should see “Cubic Subdivision” among the available options. Select “Cubic Subdivision” to enable this infill pattern.

6. Adjust Other Settings: You can also modify other settings such as layer height, print speed, and wall thickness as needed.

7. After that you can slice and put Gcode files to print. It will then print the model with Cubic Subdivision infill.

Advantages Of Using Cubic Subdivision:

Let’s look at the Cubic Subdivision Infill advantages one by one:

Strength:

The Cubic subdivision is often known for its balance between robustness and consumption of material. This 3D infill pattern is engineered to offer strength uniformly in all directions.

Material Efficiency:

The cubic subdivision infill pattern is unique because it creates a three-dimensional grid within the object, with each cell in the grid being a small cube. This pattern is more efficient than other infill patterns because it uses less material to achieve the same level of strength.

Faster Print Times:

The cubic subdivision infill pattern is unique because it subdivides the interior of the print into smaller cubes as it goes deeper into the print. This means that the outer layers of the print have larger cubes, while the inner layers have smaller cubes. This is advantageous because it provides a good balance between strength and material usage.

The faster print time comes from the fact that the printer doesn’t have to move as much when creating the infill. With other infill patterns, the printer has to make many small movements to create the pattern, which can slow down the print time. But with the cubic subdivision infill, the printer can make fewer, larger movements, which speeds up the print time.

Better Top Layer Quality:

The top layer of a 3D print is crucial as it is often the most visible part of the print and can significantly affect the overall appearance and quality of the final product. With the cubic subdivision infill, the top layer benefits from a more uniform support structure underneath. This is because the subdivided cubes provide a more even distribution of material, which in turn leads to a smoother and more consistent top layer.

Versatility:

Cubic subdivision infill is versatile because it provides strength in all directions, uses less material than other infill types, and can be adjusted to fit the specific needs of the print. This makes it ideal for a wide range of 3D printing applications.

From architectural models to medical prosthetics, the cubic subdivision infill can be used in a variety of 3D printing applications due to its versatility.